Cutting room tables are key equipment in the upholstery, furniture and clothing manufacturing industry. Therefore, while choosing a perfect cutting room table, there are a few important considerations to remember. Fortunately, this blog is here to guide you through the entire process of headhunting and making the best selection.

Manufacturers of cut materials, packaging, displays, and signage must append their ongoing production with the increase in small batch productions. If some manufacturer is still unable to increase the production pace, the exponentially increasing consumer demands and ever-expanding competition in the retail industry are to blame for this.

But often, bad quality or efficient cutting technologies are also to be blamed. Therefore, as a business owner, you should ensure that your production workforce gets the perfect equipment to match industry quality and demand.

So, install your cutting room with a perfect cutting table to meet the current demand manufacturing market.

Also read: Rotary Cutting Machines For The Home Sewing Enthusiast: What You Need To Know

Finding the perfect cutting room table is child's play if you ask yourself these questions before making the purchase. These questions will enlighten you about your choice of selection. Let us dig further deep to understand these questions.

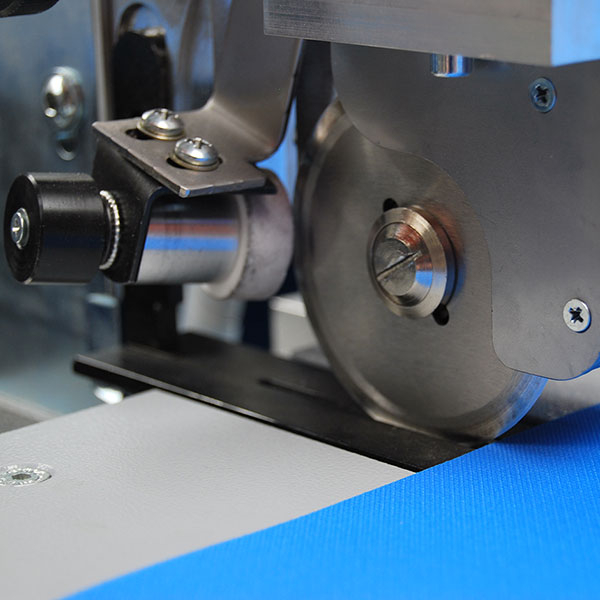

The cutting table type and size largely depend upon the type of product you are dealing with or manufacturing. So ponder about it whether you are dealing with the display or corrugated material or printed or unprinted fabric. The type of fabric required to be cut or worked on requires a specialized cutting table. It would help if you remembered that the requirements of quality demanded by a furniture-making company requiring upholstery are far different from a retail store dealing in the clothing industry. Therefore devise a good plan and search for a cutting table that could match the high-speed cutting of samples as well as the high speed and precision of cutting printed/unprinted material for signage displays.

Quality finishing means a happy customer. So no matter what industry you are dealing in, ensure you provide impeccable cutting quality. Whether cutting upholstery fabric for a furniture manufacturing company or producing products for clothing retail outlets, ensure your cutting room table has the desired quality. If you have multiple clients from different industries, your cutting table must be a versatile pick.

If you are dealing with long fabrics, your cutting table must have the desired setup and size to handle large fabric when cutting. It is always important to consider not only the desired space size but also leave enough room for the operator to move around.

Often finding a perfect cutting table is hard because of bottlenecks waiting to hamper your selection. Therefore, you should focus on more than just the speed of cutting the table but precision, waste elimination, and ergonomics. Once you ensure your cutting table has all these features, it is the perfect selection. Till then, you still need a long way to go.

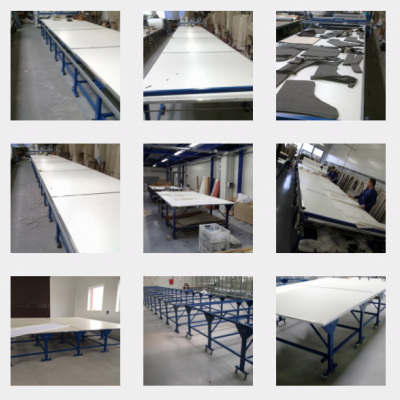

Rexel Poland is a premium manufacturer of cutting room tables of the best quality and utility.

You find versatile options for cutting room tables, including:

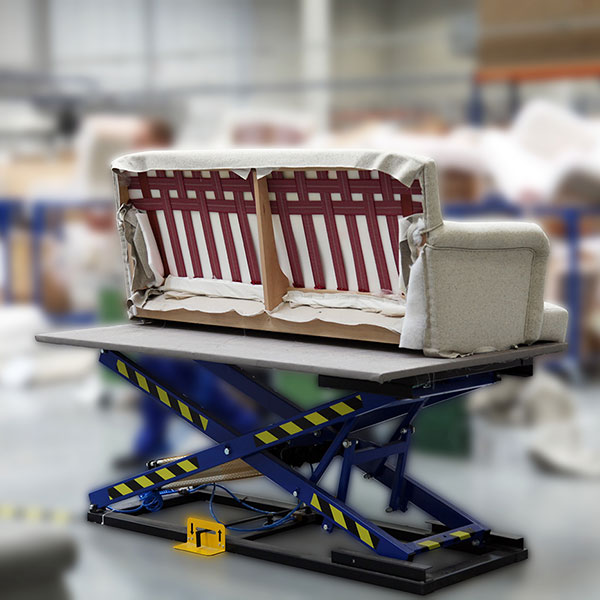

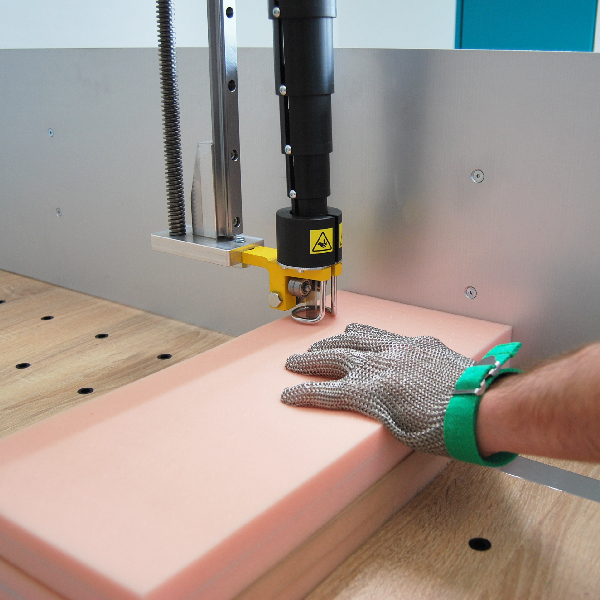

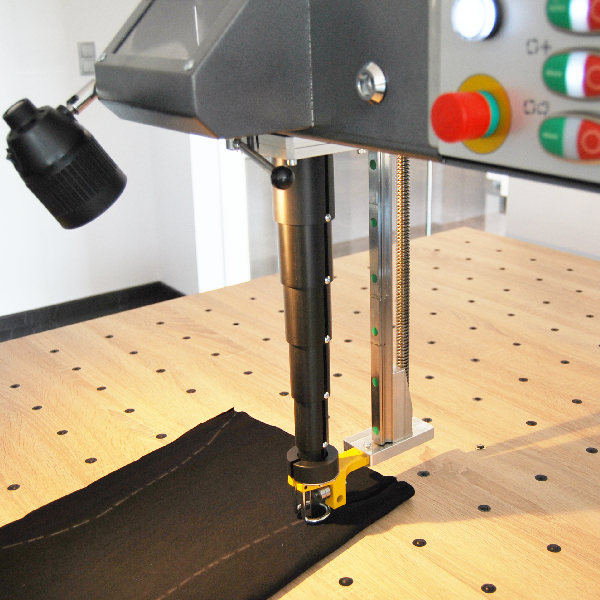

Rexel Poland manufactures a wide array of cutting room equipment as well along with Lift tables for upholstery, Band knife cutting machines for textiles and foam, Fabric rewinding and inspection machines, Pneumatic presses for chair seat and bed upholstery, Roller blinds manufacturing machines, Sewing chairs, Sewing machine stands, Mattress machines and other custom-made machines.

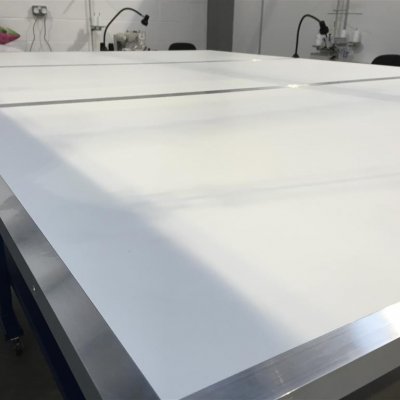

If you are looking for a basic cutting room table for your production house, consider Cutting Room Table SK-3 from Rexel Poland. The table is highly durable, with closed steel profiles imparting stability and durability.

Key Features

Visit the official website of Rexel Poland to learn more about their range of cutting room equipment, pneumatic presses, and other products.

You can also read: Selecting the Top-Notch Textile Rewinding Machines

REXEL SP. Z O.O.

ul. Radziwoja 11,

61-057 Poznań, Polska

М. +48 697 530 240

Т: +48 61 876 89 46

E: info@rexelpoland.com

On our website, we use cookies to provide you with services at the highest level, in a manner tailored to individual needs. Using the site without changing the settings for cookies means that they will be placed on your end device (browser).

To learn more about this topic, click here>