The sewing factories are where materials become the clothes we wear. Beyond the creative process, a key factor in realising the concept is the flawless integration of equipment including clothing inspection machines, sewing machine stands, band knife machines, and sewing chairs. We shall examine the inner workings of a sewing factory in this investigation, focusing on the vital inspection devices that guarantee the excellence and calibre of the finished product.

Here are some steps to streamline operations in a sewing factory:

Design and Pattern Making:

Fabric Cutting:

Sewing:

Quality Inspection:

Finishing, Packaging, and Distribution:

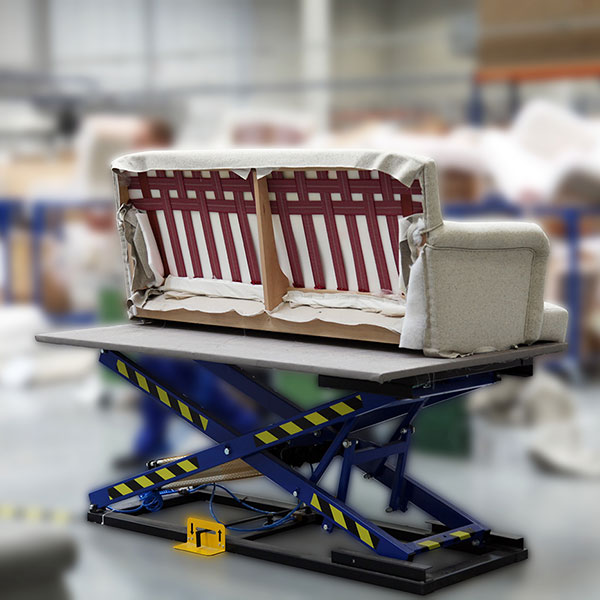

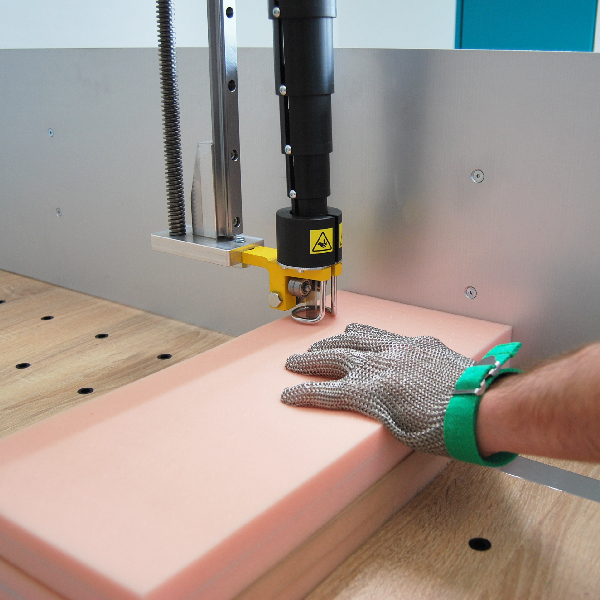

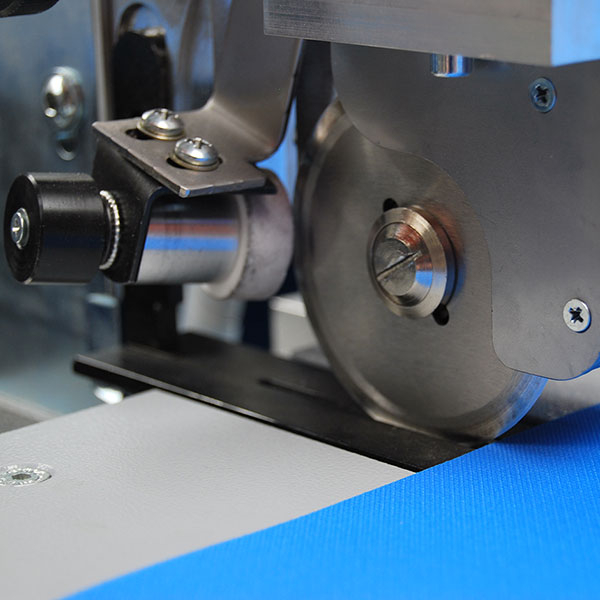

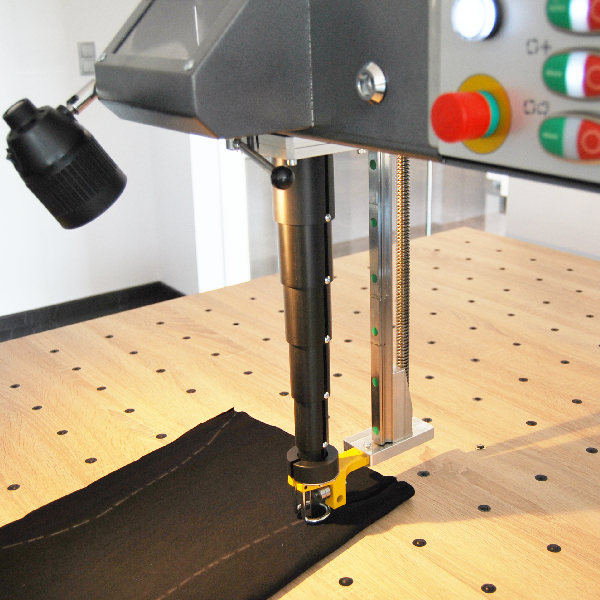

These machines from REXEL, the backbone of accurate fabric cutting, exhibit unmatched efficiency in meeting a variety of industry needs:

This powerhouse machine ensures efficient and precise multi-layer fabric cutting.

It excels in cutting fabrics of of bigger size e.g. for winter clothing.

Is a small machine, best suited for small clothing like children clothing or pet clothing where precise cut of small elements is important.

Industrial Sewing Machine Stands:

Here are some different types of sewing machine stands to support the efficiency of sewing machines -

Is mostly used for light machines like JUKI DDL 8700 or Duerkopp Adler 261.

It facilitates accurate stitching, particularly for clothes with intricate detailing. Mostly used for feed of arm machines like GLOBAL FOA series or WF series.

It provides a comfy and efficient workspace for operators while using industrial sewing machines. Mostly used for super heavy machines like Brother NEXIO BAS lub RH, JUKI AMS or MEB.

The HDP-1EK-R stand's height adjustment feature allows users to personalise their workstations and maximize comfort and productivity. Used in special machines like Dürkopp Adler 969, 869, 669; TYPICAL GC2603; JUKI MS-3580 Series, etc.

For sewing machine operators, comfort is essential, and REXEL offers a range of industrial chairs designed for extended use in a manufacturing environment:

The KT-1 blends comfort and utility with a rotating design that makes it simple to access various workstation areas.

Due to its plywood construction, the KT-2 is a great option for people who want style without sacrificing functionality because it is both durable and stylish.

With its gas cylinder height adjustment feature, the KT-3 meets a range of requirements and provides comfortable seating for long work hours.

With the smooth integration of plywood style and gas cylinder flexibility, the KT-4 offers users a cozy and supportive chair that is ideal for extended sewing sessions.

Clothing Inspection Machines:

At the end of the manufacturing process, garment inspection machines carefully check every item of clothing for flaws. These devices use sophisticated cameras and sensors to identify flaws in the fabric, stitching, or overall construction. After that, operators will be able to decide for themselves whether a garment satisfies the high standards of quality that the sewing factory has set.

Conclusion:

Precision and efficiency are non-negotiable in sewing factories as the dance of threads continues. REXEL makes a big contribution to this dance with its state-of-the-art band knife machines, ergonomic sewing machine stands, and cozy chairs. The use of clothing inspection equipment demonstrates the dedication to providing the best possible clothing. For three decades, REXEL has been a mainstay in the cutting equipment industry, influencing the development of sewing factories and guaranteeing that the clothing produced satisfies the demanding standards of the contemporary fashion industry.

You Can Also Read: Rexel Band Knives: The Ultimate Cutting Solution for Fabric, Foam, Filter and Insulation Industries

REXEL SP. Z O.O.

ul. Radziwoja 11,

61-057 Poznań, Polska

М. +48 697 530 240

Т: +48 61 876 89 46

E: info@rexelpoland.com

On our website, we use cookies to provide you with services at the highest level, in a manner tailored to individual needs. Using the site without changing the settings for cookies means that they will be placed on your end device (browser).

To learn more about this topic, click here>