The complex procedures of an upholstery factory are the foundation of high-quality upholstery in the furniture manufacturing industry. A combination of state-of-the-art equipment and expert craftsmanship works behind the scenes to turn raw materials into beautiful furniture. We explore the intriguing world of upholstery companies in this investigation, illuminating important procedures and the function of cutting-edge machinery.

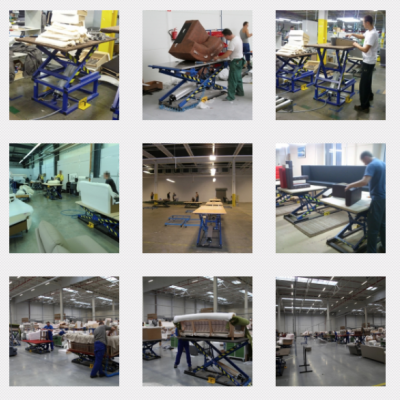

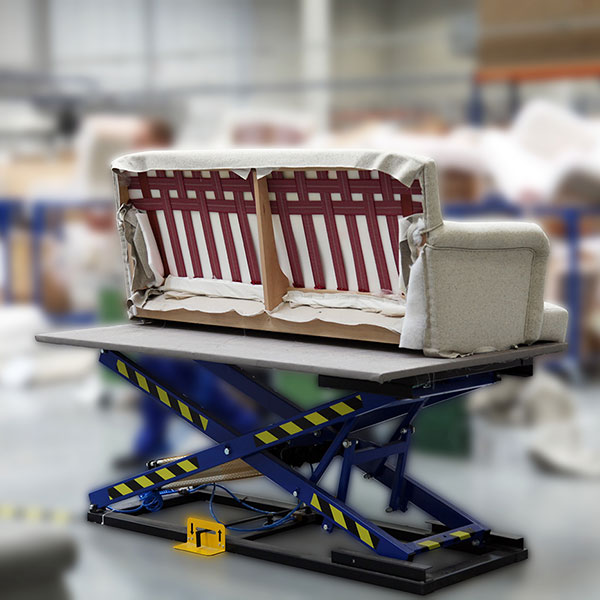

The Basics: Lifting Table for Upholstery

A vital piece of machinery, the lifting table for upholstery, is located at the centre of every upholstery facility. This adaptable gadget makes material handling more effective by enabling workers to change the height of the table to suit the task at hand. The lifting table lowers the chance of error and improves precision by offering a stable surface for a variety of operations. Its hydraulic or electric lifting mechanism promotes a comfortable and effective working environment by supporting workers' ergonomic needs in addition to helping with material location. In addition, the lifting table frequently has safety measures such as locking mechanisms, guaranteeing that it satisfies the strict safety requirements of the industry.

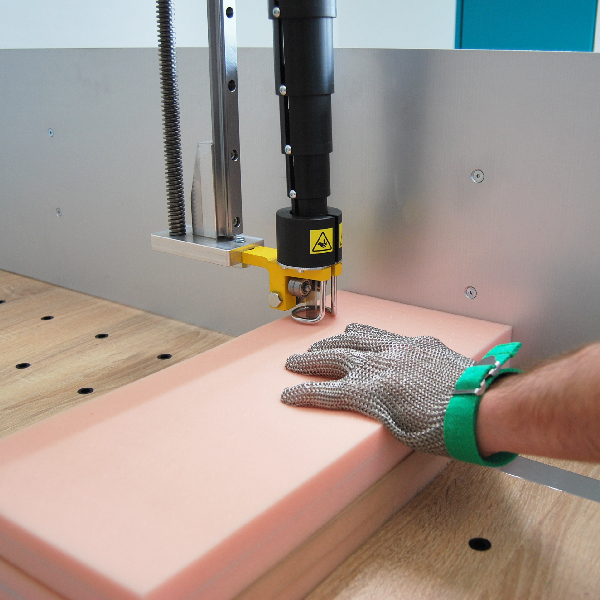

Cutting-Edge Accuracy: Upholstery Foam Band Knife Machine

Upholstery requires precision, and the band knife machine for upholstery foam is essential to achieving that precision. With precision and grace, this state-of-the-art device cuts through foam materials with its razor-sharp blade. The outcome is precisely cut foam pieces to offer a smooth and cosy upholstery finish. Additionally, the band knife machine has changeable settings that let artisans customise the cutting procedure to fit various foam thicknesses and densities. Furthermore, contemporary versions of this apparatus might integrate computer numerical control (CNC) technology, facilitating automated and incredibly accurate cutting for complex upholstery patterns.

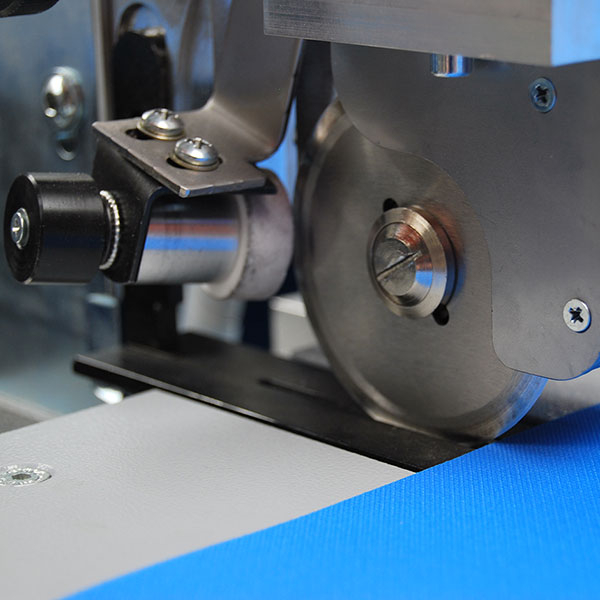

Fabric Handling: Fabric Inspection and Rewinding Machines

The manufacturing line of the upholstery plant is not complete without the fabric rewinding and fabric inspection machines. The neatly arranged rolls of fabric are ready for the production process by the fabric rewinding machine. Concurrently, the machine for inspecting fabrics thoroughly checks fabrics for flaws, guaranteeing that the upholstery process uses only faultless materials. The fabric rewinding machine effectively manages and maximises the usage of fabric rolls, resulting in time savings as well as reduced material waste. With its sophisticated sensors and illumination, the fabric inspection machine finds even the smallest defects or abnormalities in the fabric, helping to produce upholstered items that are both visually stunning and of the highest calibre.

Also Read: How Does A Sewing Factory Work

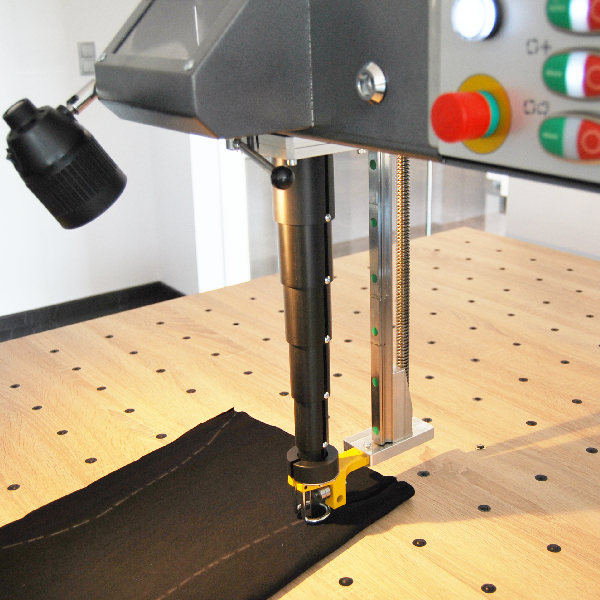

Exceptional Stitching: Commercial Sewing Machine Stand

Upholstery consists of more than simply fabric; the fine stitching connects all the parts. For precise sewing, the industrial sewing machine stand offers a sturdy foundation. This stand is used by artisans to make strong, visually appealing seams. This adds to the upholstered furniture's overall quality and lifespan. There are many stitching possibilities with industrial sewing machines. It makes things possible to include a wide range of styles and patterns in the upholstery. Because the stand is made to absorb vibrations, the sewing machine will run smoothly and the quality of the stitches will remain constant. Furthermore, the ergonomic elements incorporated into the stand's design facilitate the upholsterer's comfort during extended sewing sessions, hence augmenting overall productivity and workmanship.

Innovations in Pneumatic Presses: Meeting Industry Demands

Upholstery firms are using cutting-edge machinery to satisfy the demands of contemporary furniture making as technology progresses. Renowned industry participant Rexel Poland leads the way with its state-of-the-art pneumatic presses that are tailored to different upholstery requirements.

A notable addition, the NEW Pneumatic Press for Upholstery PDM-3B boasts cutting-edge technology that increases manufacturing productivity and efficiency. It is an invaluable tool for upholstery production because of its sturdy construction and intuitive interface.

The Pneumatic Press for Upholstered Seats PDP-1 and PDK-1 provide accuracy and dependability for upholstered seats. These devices can tackle the complexities of seat upholstery, guaranteeing a reliable and superior finish.

The Pneumatic Press with Drawstring System PDK-2/PDS opens up the door for distinctive design aspects. With the help of this drawstring system, artisans can experiment and give upholstered furniture a unique look.

Compact and powerful, the Pneumatic Press for Upholstery PDM-1 Mini is ideal for smaller-scale tasks without sacrificing quality. It is the best option for a variety of upholstery applications due to its effectiveness and versatility.

The tall press Pneumatic Press for Upholstery PDM-1/HD is ideal for heavy-duty upholstery work. With its sturdy construction and capacity to manage the demands of mass production, this machine guarantees accuracy and longevity in each piece it produces.

Rexel Poland's Commitment to Excellence:

Pneumatic presses for bed and chair upholstery are a dependable source that Rexel Poland has established. Rexel Poland offers high-quality machinery that meets industry requirements and pushes the frontiers of innovation.

Conclusion:

A factory that manufactures upholstery is a symphony of modern technology, skill, and perfection. Every element, from fabric handling tools to band knife machines, and lifting tables to industrial sewing machine stands, is essential to creating the ideal piece of upholstered furniture. The upholstery manufacturing business experiences sustained expansion. Therefore, improved standards are vital due to advancements such as the pneumatic presses manufactured by Rexel Poland. With the way that custom and technology are coming together, upholstery has a bright future ahead of it.

You Can Also Read: Rexel Band Knives: The Ultimate Cutting Solution for Fabric, Foam, Filter and Insulation Industries

REXEL SP. Z O.O.

ul. Radziwoja 11,

61-057 Poznań, Polska

М. +48 697 530 240

Т: +48 61 876 89 46

E: info@rexelpoland.com

On our website, we use cookies to provide you with services at the highest level, in a manner tailored to individual needs. Using the site without changing the settings for cookies means that they will be placed on your end device (browser).

To learn more about this topic, click here>