With an increasing number of offices worldwide, there’s an increasing demand for premium office furniture production with great quality and efficiency. While earlier it used to take weeks to prepare upholstered furniture, now it takes only a few days thanks to advanced machinery and tools, like PDK-1 and PDP-1 presses, that maximise upholstery production, particularly office chairs.

In this article, we’ll explore how pneumatic presses, such as the PDK-1 and PDP-1, and how they are crucial to speed up the process of manufacturing modern upholstered furniture.

Pneumatic presses are used in various industrial applications, like upholstery. These presses use compressed air to apply force at a uniform level to cover upholstery materials on chair frames seamlessly. Thanks to these pressures, the craftsmen can achieve the desired quality finishes that meet the standards of furniture manufacturing standards.

Here are some major benefits of leveraging pneumatic presses in the upholstery of office chairs:

Pneumatic presses perfectly fasten and stretch upholstery fabric with consistent force for a uniform application. Due to this consistent tension, it keeps chairs from sagging and wrinkling. This provides a polished look for the chair while improving longevity.

Due to the strong binding force between fabric, upholstery foam, and chipboard, pneumatic presses help in secure attachment. This further enables the material to increase the life of office chairs even with repeated use.

Due to automation and speed acceleration, pneumatic presses increase the productivity of furniture upholstery. It highly reduces the time required for upholstering backrests and seats of office chairs. So, the manufacturers can finish the deadlines without compromising on product quality.

Due to the dual-hand control mechanism of the two-hand button-controlled models, like the PDK-1 and PDP-1, there’s enhanced operator safety. This is because the operator can use both hands to trigger the press. This ensures proper operation while reducing inadvertent activation possibility.

```

PDK-1 Pneumatic Press

PDK-1 pneumatic press is suitable for upholstery tools of modest to moderate sizes. Due to its versatile features and durable construction, it is a great choice for manufacturing office chairs.

Specifications:

Model: PDK-1

Working Pressure: 3-6 bar (43.5-87 PSI)

Adjustable Tabletop Height: 750 mm (29.52")

Pressure Regulator: Yes

Pneumatic Cylinder: D63x500

Key characteristics:

The adjustable pressure regulator enables accurate control over the pressing force, and the two-hand button control mechanism provides safe operation.

The PDK-1 expedites turnaround times by optimizing the upholstery process, which increases production efficiency. Max. seat thickness: 330 mm

Operator comfort and convenience of use are enhanced by the ability to adjust the press to a suitable height thanks to the long stroke of the pneumatic cylinder and lower telescopic stand.

PDP-1 Pneumatic Press

PDP-1 is a perfect mini variant for small-piece upholstery. Since it is compact, it can adjust to any table in a workshop with restricted space.

Specifications:

Model: PDP-1

Cushion Diameter: 750 mm (29.52")

Overall Dimensions: 600 x 600 x 900 mm (23.62" x 23.62" x 35.43")

Working Pressure: 3-6 bar (43.5-87 PSI)

Two-Button Safety Start System: Yes

Pneumatic Cylinder: D63x200

Pressure Regulator: Yes

Key characteristics:

The PDP-1 considerably raises production, quality, and efficiency in chair manufacture despite its reduced size. Max. seat thickness: 60 mm

The PDP-1 is simple to operate and offers even and controlled pressing of upholstery materials with to its rotational cushion and hand wheel for pressure adjustment.

Similar to the PDK-1, the PDP-1 has an air pressure regulator and a two-hand button control mechanism for accurate and safe operation.

The presses PDK-1/P and PDP-1/P are made with so called Positioning system. One can distinguish both types by the color of the START buttons:

- NO POSITIONING - RED BUTTONS: In standard press without positioning the piston goes all the way down, if operator lets go the buttons too early the piston returns to starting position

- POSITIONING - GREEN BUTTONS: Piston goes down only when buttons are pressed. This solution allows for more precise pressure adjustment of the seats.

Also Read: How to make a roller blind?

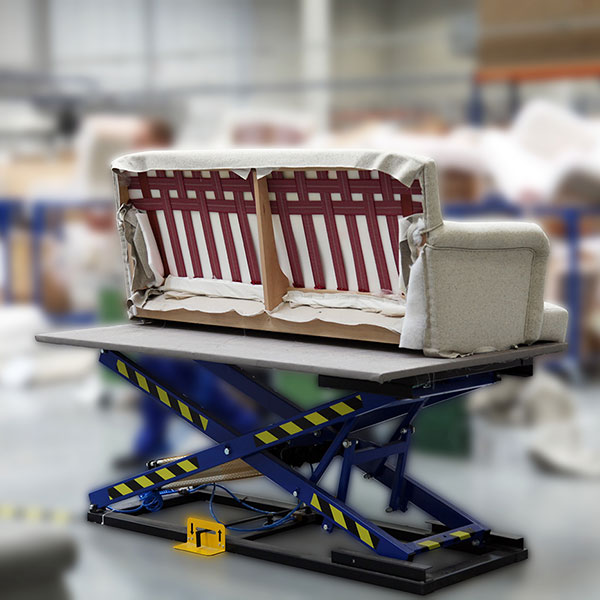

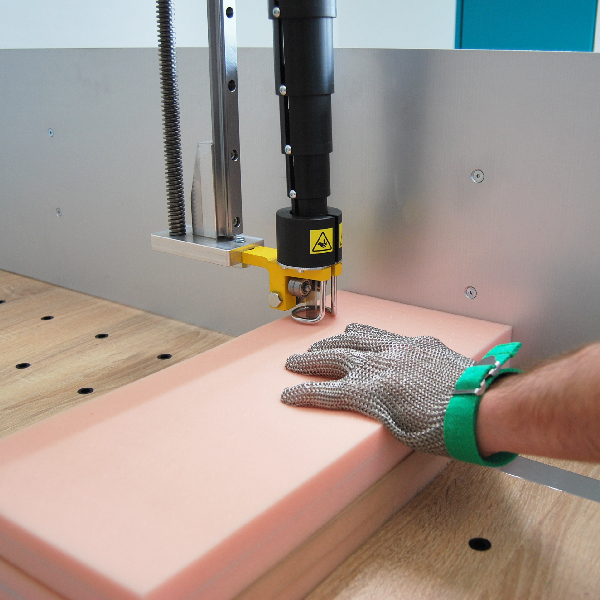

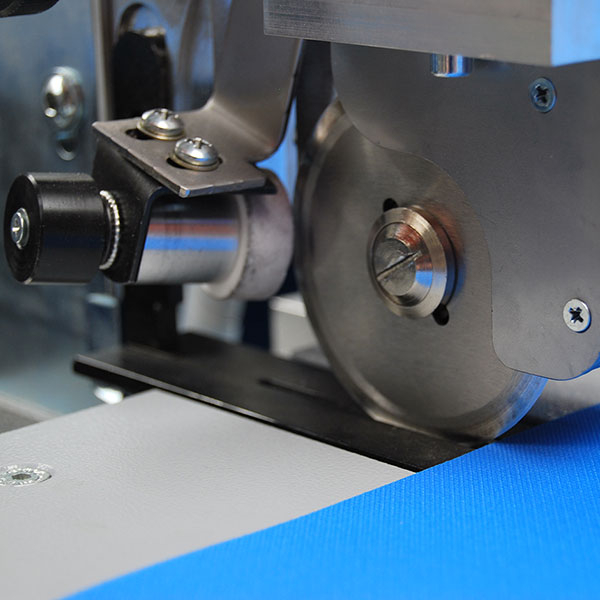

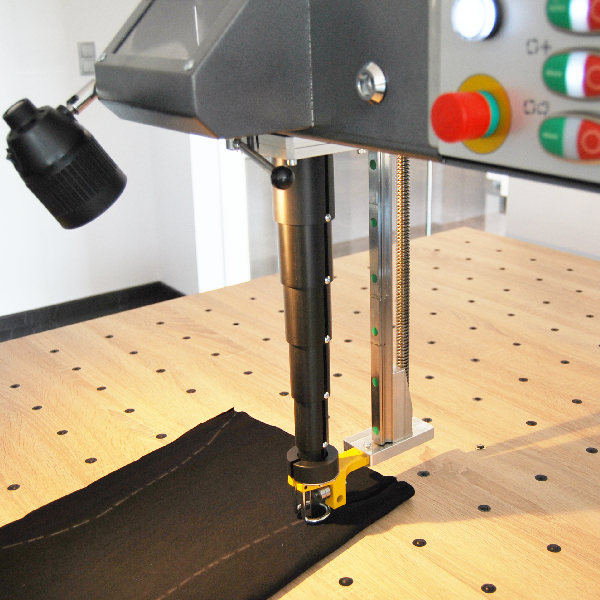

Pneumatic presses should be used in conjunction with other necessary upholstery workshop equipment, such as pneumatic lift tables, upholstery cutting tables, and upholstery workbenches, to optimize their advantages.

Cutting Table for Upholstery

Pneumatic Lift Table

Upholstery Workbench

Conclusion

PDK-1 and PDP-1 pneumatic presses are innovative tools in the upholstery sector, especially for manufacturing office chairs. Craftsmen can use them with other essential equipment, like cutting tables, pneumatic lift tables, and upholstery workbenches. With that, they can easily streamline their workflow while producing premium quality office chairs with maximum longevity and comfort.

Thanks to these state-of-the-art technologies, operator working conditions and productivity increase to a great extent. This further leads to a more contented workforce along with increased production. The office chair manufacturers can buy these innovative pneumatic presses from REXEL Poland to optimize their work processes. Find more information about these tools on the official website.

You Can Also Read: The Ultrasonic Manual Cutter TTS-400 Redefines Synthetic Material Cutting

REXEL SP. Z O.O.

ul. Radziwoja 11,

61-057 Poznań, Polska

М. +48 697 530 240

Т: +48 61 876 89 46

E: info@rexelpoland.com

On our website, we use cookies to provide you with services at the highest level, in a manner tailored to individual needs. Using the site without changing the settings for cookies means that they will be placed on your end device (browser).

To learn more about this topic, click here>