You can make a roller blind that is specifically tailored to fit your window with the right supplies and a little perseverance. This comprehensive guide includes all the necessary tools and techniques to create a roller blind.

Materials You Will Need

To create a roller blind, gather the following materials:

Step-by-Step Instructions

Step 1: Prepare a Rectangular, Window-Sized Piece of Fabric

To estimate the size of the cloth you need, start by taking precise measurements of your window. Trim the fabric to a rectangular shape that fits the size of the window. To prevent fraying, make sure the edges are neat and straight.

Step 2: Attach the Fabric to the Tube

Take off the tube's cover attached to the adhesive tape. Make sure there is the same amount of room on both sides as you carefully match the cloth with the tube. Firmly press the fabric onto the adhesive to secure it to the tube. To guarantee that the fabric lays flat and evenly, smooth out any wrinkles.

Step 3: Apply Mylar Adhesive Tape to the Bottom Edge of the Fabric

Next, line the bottom border of the cloth with Mylar sticky tape. In this process, the cloth is strengthened and ready for the bottom bar. The edge is strengthened and made more durable by the Mylar tape.

Step 4: Staple the Mylar Tape and Fold It

To attach the Mylar tape to the fabric, use a stapler. you guarantee that the tape is securely fastened, make sure you staple along its length. After the fabric is stapled, fold it over the tape to form a tidy, finished edge. This technique guarantees that the cloth is firmly fastened to tubes that have a groove.

Step 5: Insert the Bottom Bar

Lastly, fold the fabric over the Mylar tape to create a pocket, then place the bottom bar into it. By adding weight, the bottom bar makes the blind hang correctly and function properly.

Optional Equipment for Testing and Packaging

REXEL Poland offers an extensive range of specialized machines to help you manufacture roller blinds. Some of the key machines to consider include:

These tables offer precise and sturdy surfaces for cutting cloth. Durability and accurate cutting are guaranteed by the sturdy design, which is essential for preserving consistency and quality in roller blind manufacturing. Every model has special characteristics designed to meet various production requirements. For larger blinds, for instance, the UK-1 MAX delivers the longest cutting length possible, and the UK-2 ECO offers an affordable option without sacrificing quality.

Manual Measuring Stops PR-11:

Use the PR-11 to guarantee accurate measurements for every blind. This equipment makes measurement rapid and precise, lowering the possibility of mistakes and guaranteeing that each blind produced satisfies precise requirements.

Roller Blind Fabric Winding Unit ZT-1:

To ensure tight, consistent rolls, automate the winding process. By ensuring that every roll of fabric is wound uniformly and securely, the ZT-1 helps to prevent damage and improves the efficiency of the assembly procedures that follow. For large-scale production when consistency and time management are crucial, this unit is perfect.

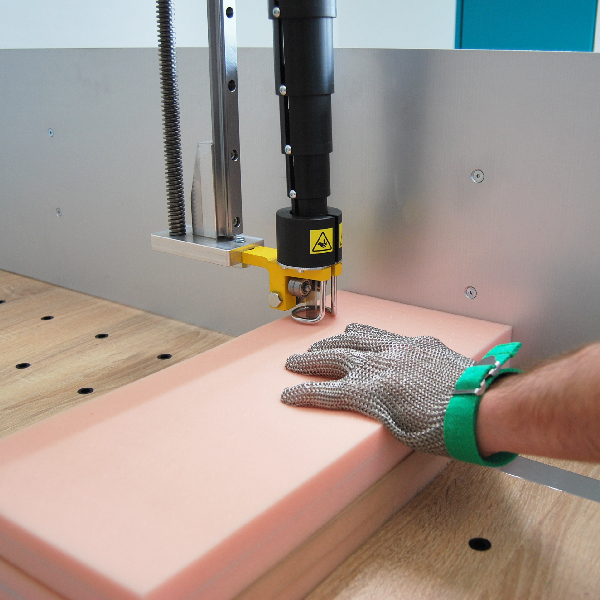

Ultrasonic Knife Upgrade Set for UK-2 ECO:

For cleaner cuts, and where the fabric is made with at least 50% of artificial component, upgrade your cutting surface with an ultrasonic knife. This upgrading package guarantees a clean cut line and minimizes fraying. Because of its accuracy and versatility in handling materials, ultrasonic cutting is a crucial component of production of superior quality.

Roller Blinds Control Lift WK-1:

Utilizing the WK-1, regulate the lifting mechanism during assembly. This instrument facilitates accurate fabric and component alignment, guaranteeing seamless operation of every blind. The operation and longevity of roller blinds depend on proper alignment, which the WK-1 gives you the control you need to accomplish.

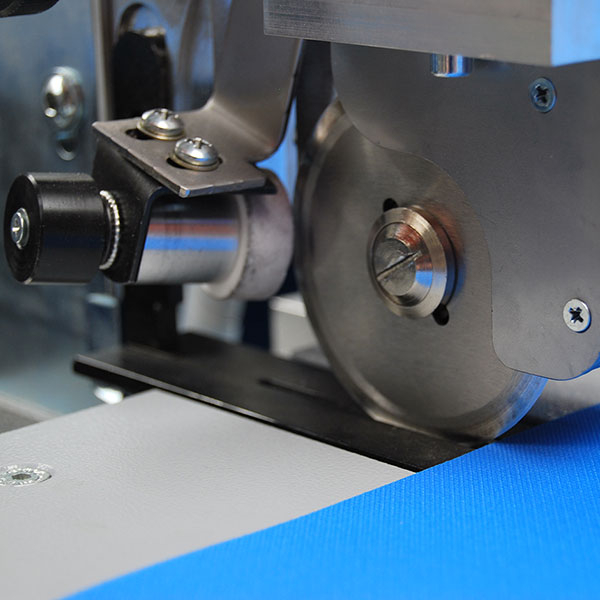

Vertical Curtain Cutting Machine UCF-1:

The UCF-1 may be used to precisely cut vertical curtains. With its precise and clean cuts, this machine is made especially for cutting vertical blinds, giving a polished appearance. The UCF-1 is a great addition to any vertical blind production line because it can handle many fabric varieties.

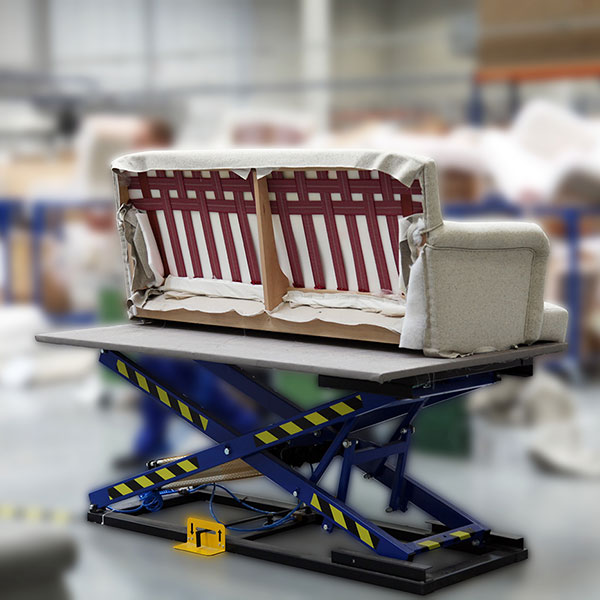

Inspection Hoists WK-1/HD and WK-2/HD:

With the help of these hoists, it is simple to lift and inspect the completed goods to make sure they adhere to all quality requirements before packaging and shipping. Because of their ability to support a range of weights and sizes, the WK-1/HD and WK-2/HD are adaptable instruments for the inspection process.

Measuring Bar SUW-2:

In blind production, precise measurement of fabric lengths is essential, and the SUW-2 measuring bar offers the accuracy required for this work. This simple-to-use instrument guarantees that each piece of cloth is cut to the precise length needed, cutting waste and raising production efficiency levels.

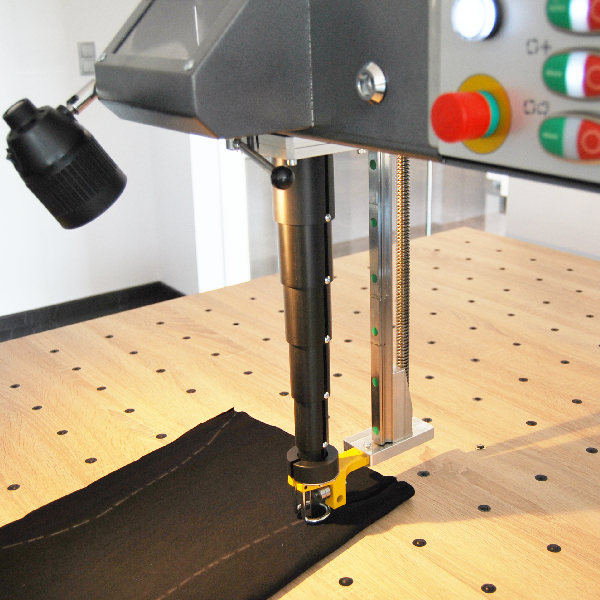

Ultrasonic Manual Cutter for Textiles TTS-400:

The TTS-400 is a portable cutter with ultrasonic technology for smooth and clean cuts, allowing for quick adjustments and precise cutting. This tool is ideal for making quick modifications and making sure that every piece of fabric satisfies the requirements. Due to its adaptability, it is a necessary tool for every production line that produces roller blinds.

Conclusion

When the proper supplies and techniques are used, making your own roller blind may be a simple and entertaining project. To improve production accuracy and efficiency, REXEL Poland provides a range of machinery to manufacturers of roller blinds. These equipment and procedures will assist you in achieving professional results whether you're producing a single blind for your home or putting up a production line.

You Can Also Check Out Our Latest Blog Post: The Ultrasonic Manual Cutter TTS-400 Redefines Synthetic Material Cutting

REXEL SP. Z O.O.

ul. Radziwoja 11,

61-057 Poznań, Polska

М. +48 697 530 240

Т: +48 61 876 89 46

E: info@rexelpoland.com

On our website, we use cookies to provide you with services at the highest level, in a manner tailored to individual needs. Using the site without changing the settings for cookies means that they will be placed on your end device (browser).

To learn more about this topic, click here>