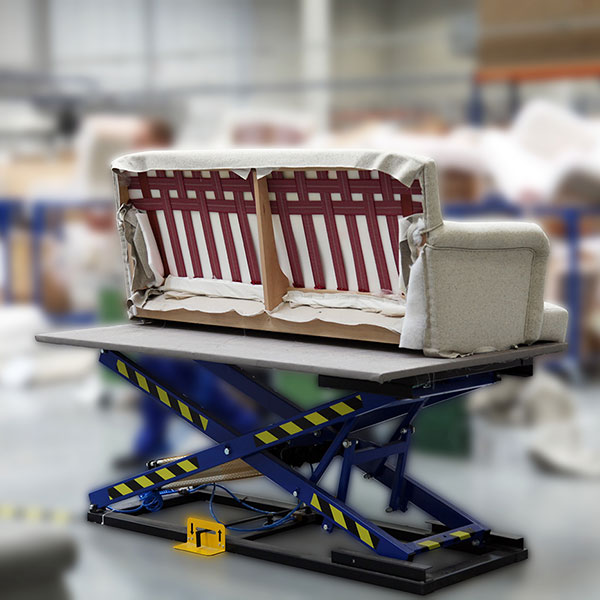

In the world of furniture manufacturing, it’s vital to keep precision and efficiency in mind. For that, keeping up with innovative equipment is a must. The businesses that deal in sofa production must use innovative equipment, like pneumatic lift tables, to boost the quality of their products while improving productivity. Among the various options available the best ones are the ST-4 and ST-4B pneumatic lifting tables for gluing. Using these advanced tables, it is easier to streamline the entire process of gluing while increasing worker safety and ergonomics.

It is specialized equipment that adjusts its height and is also able to rotate the tabletop for handling manufacturing tasks. All pneumatic components, are enclosed inside the table so the glue does not get inside. Tabletop is made of stainless steel that allows for easy cleaning.

1. Improved Ergonomics

Tasks like upholstering and gluing usually need workers to manage work while being in awkward positions for long durations. But with pneumatic lift tables, they can eliminate these woes while making better height adjustments – ranging from 500 mm to 820 mm. Due to its rotational ability, you can make sure that workers can work comfortably without any fear of injury and fatigue.

2. Improved Efficiency

Thanks to ST-4 and ST-4B tables, it is easier to streamline the entire process of gluing with better stability. The rotating tabletop can lock itself into around 12 distinct positions via its pneumatic actuator with foot control (ST-4B). This enables workers to easily access various angles of a sofa without any need for manual repositioning. It helps enhance productivity while decreasing downtime by around 14% than conventional upholstery trestles. ST-4 can be locked in two positions using manual locking rod.

3. Energy Efficiency

When you switch to a pneumatic lift table, the worker spends less energy while saving time. According to studies, use of these tables saves around 15% energy than traditional trestles.

4. Better Safety and Durability

Crafted from solid steel profiles, the ST-4 and ST-4B tables are ideal for use for long durations in challenging industrial environments. Due to the enclosed pneumatic components, it easily protect the system from glue damage without any interruption. The tables are equipped with locking valves that prevent the table from falling down when the air is disconnected.

1. Prepare the Table

Before you begin, make sure the table is well-connected to a pneumatic supply with around 6 bar working pressure. Also, make sure that all components are operational.

2. Height adjustment

Adjust the height of the table with the foot pedal to a comfortable height so that a worker can work in a comfortable position. This helps in reducing strain in their body while gluing.

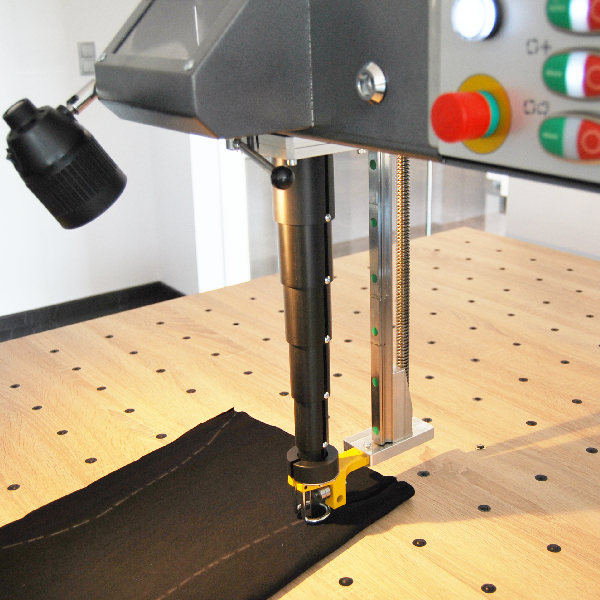

3. Lock the Tabletop

Certain tasks need a specific tabletop position for working. For that, lock the tabletop using a foot-controlled actuator in any desired position that works well. It helps them to reach even hard-to-reach areas with ease.

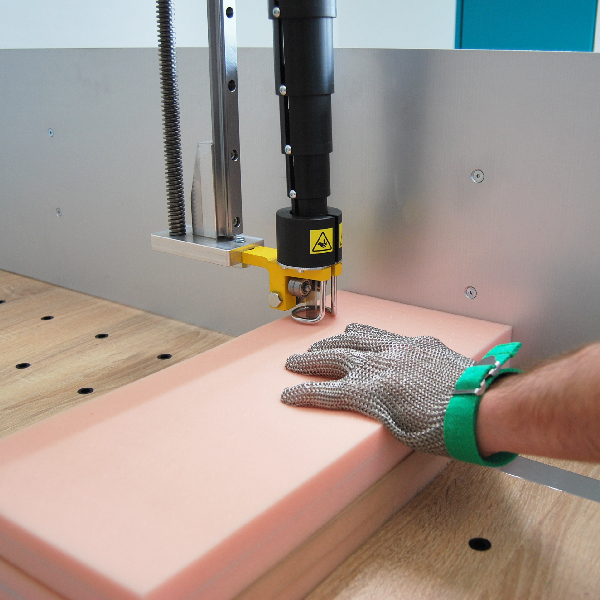

4. Gluing

Once the table is positioned securely, proceed with the gluing part. A stable surface with adjustable angles makes sure you can precisely apply glue to boost the overall quality of the end product.

5. Store It

Once the task is done, lower the table to its lowest position after proper cleaning. Due to its enclosed pneumatic parts, one can easily clean the table while preventing any damage to the table.

Thanks to advanced pneumatic tables, you can easily meet the requirements of modern furniture manufacturing without any hassle. You can integrate this equipment in your production unit for:

Other Applications:

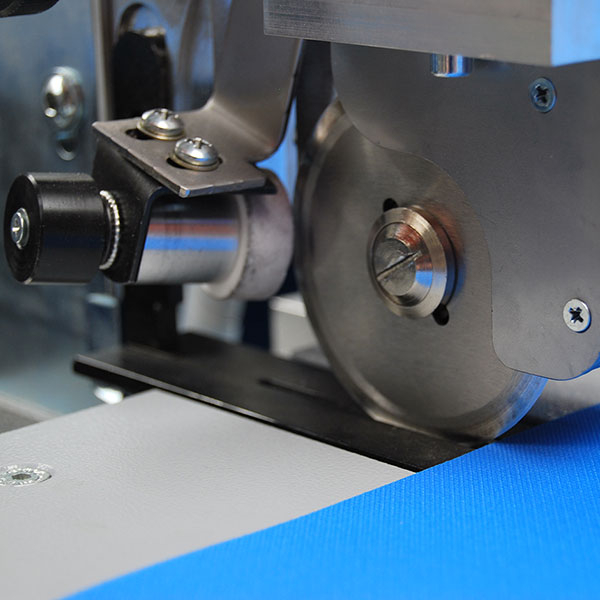

Although the pneumatic tables are majorly ideal for handling gluing work, these are also ideal for other applications in the sofa production industry. Some of these applications include:

Conclusion

Integrating pneumatic lift tables, like ST-4 and ST-4B, for the production of sofas to transform how you work. Its advanced features, like rotating tabletops, adjustable height, and enclosed pneumatic systems, enable better safety, efficiency, and product quality. So, don’t remain stuck to old equipment. Simply invest in innovative solutions to take sofa production to new heights.

REXEL SP. Z O.O.

ul. Radziwoja 11,

61-057 Poznań, Polska

М. +48 697 530 240

Т: +48 61 876 89 46

E: info@rexelpoland.com

On our website, we use cookies to provide you with services at the highest level, in a manner tailored to individual needs. Using the site without changing the settings for cookies means that they will be placed on your end device (browser).

To learn more about this topic, click here>